Over 40 years of building forklifts have culminated in the XF series from Hangcha Group. This experience, combined with the latest in forklift technology, the result is a line of forklifts that are efficient, environmentally conscious, comfortable, reliable, and safe. The XF series represents the true do it all forklift from Hangcha Group.

GCT K21/25 LPG Engines

The GCT K21/25 engines comply with North American EPA emissions standards. Although they meet these standards, they still have the power and torque to get the job done. These engines are also electronically controlled to increase the fuel economy and the reliability of the trucks.

Kubota V2607 Diesel Engine

Hangcha uses the powerful Kubota diesel engine in our pneumatic tire forklifts. The Kubota engine is Tier 4F compliant. The engine uses common rail fuel systems, diesel oxidation catalysts (DOC), and diesel particulate filters (DPF) to meet the Tier 4F compliance. This engine helps the Hangcha forklifts maximize their efficiency and reliability for the end-user.

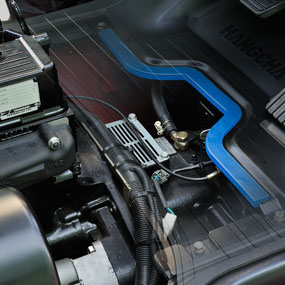

In developing the XF Series, comfort and ease of operation were carefully considered. For example, vibration levels were improved by adding compound engine dampers and full-floating powertrain mounts. The rubber damper between the frame and the steering axle, the compound engine damper, and the full floating powertrain achieves a flexible connection between the frame and the driving system. As a result, vibrations are significantly reduced to increase operator comfort. The increased capacity exhaust muffler, intake, and noise shield technology significantly lower the forklift’s noise levels for the operator. Comfortable operating environments for operators contribute to increased productivity.

Easy-to-See Display

The new relocated, easy-to-see LCD instrument display lets the operator check on all aspects of operational status with a glance. The instrument display consists of a 4″ color LCD screen, four interactive buttons, and one CAN bus communication function. The communication protocol is compatible with CANopen and SAE J1939 standards.

Ergonomic Operator Compartment

1. The new automobile-style light/turn-signal stalk and the forward-reverse lever are ergonomically designed and arranged to improve comfort and productivity.

2. The small-diameter steering wheel, with tilt adjustment, provides an optimal driving position for the operator. The superior responsiveness of the steering wheel optimizes maneuverability even in narrow spaces.3. The parking brake was developed to reduce the operational force by 30%.

4. The automobile-style suspended pedals provide a more ergonomic, operator centered experience.

5. Optimal visibility in all directions creates the best conditions for relaxed and safe operation. The front lifting cylinders were redesigned with a smaller outer diameter to give the operator superior forward visibility. The double lifting cylinders also provide better forward visibility.

6. The foot space is now 90% wider to significantly reduce operator fatigue. The new wide, non-slip step makes getting in and out of the forklift safe and easy.

7. The easy-to-operate levers provide total load handling operation. The armrest is provided to reduce fatigue. The optional electro-hydraulic proportional control system gives the forklift the ability to make load handling more sensitive and precise.

By focusing on enhancing reliability and reducing downtime, the XF series is able to increase productivity for its end-users.

Full-Floating Transmission

The new, full-floating, aluminum alloy transmission features excellent heat dissipation and thicker discs to meet the most demanding applications.

Electronics

The new controller is integrated into all of the electrical components. It also features excellent durability in harsh temperatures, water, and vibrations. This promotes reliability in the most demanding operations.

Stamped Air Cleaner

The new stamped air cleaner features a tangential intake, double seal, and a safety filter. The air cleaner is durable, corrosion-free, and vibration-resistant. It also provides better filter efficiency and lowers intake resistance.

Rugged Design

XF series features a rugged design, stamped frame, and an engine hood. The stamped instrument panel, overhead guard, and heavy profile rail mast combine to provide excellent structural rigidity to ensure outstanding reliability and stability in heavy-duty conditions.

Optimized Cooling System

The forklifts are equipped with large capacity aluminum radiators. These radiators have optimized heat dissipation channels to enhance cooling capabilities. This keeps the engine running reliably in heavy-duty applications.

The XF series is designed to facilitate easy inspections and servicing. Easy maintenance reduces the amount of downtime cost of ownership.

1. The cover on the dash can be lifted up to easily check the brake fluid.

2. The two-piece design makes the floorboard easy to lift and remove for access to the powertrain.

3. The easy-to-operate latch provides quick access to the engine compartment.

4. The radiator cover fasteners can be turned easily by hand to enable quick inspections or servicing.

A wide range of technology is applied to ensure absolute safety for both the operator and those in the vicinity.

Operator Presence Sensing System

The operator presence sensing (OPS) system incorporates a lifting, tilting, and traveling stop function. When the operator leaves the seat, the system automatically locks the lifting/tilting functions and disables the forklift from traveling to ensure safety.

Mast Safety Device

The throttling device locks the mast in place if there is a hydraulic failure. This adds to the operational safety of the truck.

Soft Lifting/Landing System

In addition to the soft landing system, the soft lifting system is adopted (front lifting cylinders of the full free-lift stage 2 & 3 masts). As a result, the noise and shock of the mast significantly decrease when lifting material.

Locking Mechanisms

There is a locking mechanism found on the engine hood, damper, and parking brake for the operator’s safety.

Optional Rear Reverse Grip

An optional rear reverse grip with a horn button enhances operational safety while traveling in reverse.

Interactive Instrument Display

Rubber Dampener

Environmentally Friendly Engines

Efficient LED Lighting

The Electronic Controller

The New Aluminum Alloy Transmission

- Full Cabin

- Cabin Heater

- Front Window with Wiper

- Solid Pneumatic Tires

- Non-Marking Tires

- Full Suspension Seat

- Fire Extinguisher

- Higher Overhead Guard

- Rear Reverse Grip with Horn

- Customized Color

- Tilt Cylinder Cover

- Tilt Cylinder Boot

- Counterweight Grill

- Pre-Cleaner

- Radiator Screen

- LPG Swing Out Metal Bracket

- LPG Swing Down Metal Bracket

- Auxiliary Hydraulic Valve

- Electro-Hydraulic Proportional Control System

- Return Oil Filter

- Front & Rear working Light

- Wider Fork Carriage

- Wider Load Backrest

- Various Optional Attachments