XH Series High Voltage Lithium-ion Pneumatic Forklifts are new series of high voltage lithium-ion forklifts independently developed by Hangcha Group. By applying the same technology found in automobile applications, Hangcha’s high voltage forklifts are designed to outperform similar electric and internal combustion forklifts. Hangcha Group is redefining electric forklifts’ efficiency, power, and reliability with the XH Series High Voltage Lithium-ion Forklifts.

An advanced permanent magnet synchronous motor drive controller and vehicle controller are used to control the driving, lifting, braking, and steering actions of the forklift. Stable and accurate control, superior speed regulation, regenerative braking, reverse braking, protection for preventing sliding down a ramp, etc. enable safer, more effective, and more comfortable operations. The large LCD screens display the remaining battery life and have a timer, fault self-diagnosis, and mode selection. The large LCD instrument display accurately displays information about the different systems of the forklift in harsh environments. An energy-saving and environmentally friendly LED lighting system is used.

An electric proportional multiway valve, a silent hydraulic gear pump, an ergonomic joystick, and a high-pressure water-cooled permanent magnet synchronous oil pump motor are used. The load-sensing hydraulic system reduces the continuous load of the oil pump motor to increase reliability. The electrically controlled remote operating mode is simple and convenient to use. Multiple hydraulic test points are added to simplify repair and maintenance work. The hydraulic system power source uses a Casappa Gear Pump, Danfoss PVG Multiway Valve, and Danfoss Hydraulic Steering System to ensure the reliability of the forklift.

The hydraulic power brake valve with dual pressure curves enables a softer pedal feel. A multi-disc wet driving brake acting with a spring, a hydraulically released caliper parking brake system, and a forced cooling oil circuit are used to increase safety and reliability.

The widened Limited Free Lift Two Stage Mast enables higher torsion resistance of the mast & broader view. The double-speed limiting hydraulic valve circuits increase the safety of the forklift. Hydraulic pitch adjustment and side shift are provided as a part of the standard configuration.

A maintenance-free high-pressure water-cooled permanent magnet synchronous drive motor is used to increase power & efficiency. The system has protection functions in the motor to improve reliability, service life, and reduce maintenance costs. The two-stage decelerating heavy-duty Kessler drive axle with multi-disc wet driving brake and a motor are safe and reliable. The system is fully enclosed, maintenance-free, and are perfect in heavy-duty operating conditions.

The forklift features a fully enclosed integrated cabin. The cabin connects to the chassis via a four-point shock-absorbing rubber to reduce vibration. It is equipped with electric and manual tipping mechanisms to facilitate routine maintenance. The large cabin floor and ample overhead/leg space enable the driver to enter and leave the cab easily at any time. The fully enclosed cabin is heatproof, dust-proof, and waterproof. There are sunshades in the cabin and a filter at the fresh air inlet. The internal circulation fan is adjustable. The air conditioner and heater come standard and keep the cabin at a comfortable temperature. The seat is fully adjustable to increase operator comfort. All glass is safety glass. The front, rear, and top windshields are equipped with cleaners and wipers. In addition, they are also equipped with windshield defrosters.

- The operator compartment features an adjustable suspension seat, adjustable steering column, and an adjustable multi-directional armrest to allow the operator to find their ideal driving position.

-

The wide-view mast is designed to limit any obstructions in the operator’s line of sight. The enlarged opening size of the fork carriage enables a wider view, a large operation space, and excellent ergonomic design.

- The multifunctional LCD instrument panel is designed to clearly display data, functions, and monitor the forklift’s systems.

- The ergonomic joystick enables accurate control of the forklift.

The load-sensing steering system uses a single steering axle with horizontally-placed double-acting cylinders to allow the operator to easily steer the forklift.

- Both the drive and operating systems are vehicle-grade permanent magnet synchronization systems. The driving speed, gradeability, and acceleration performance rival that of internal combustion forklifts. The environmental performance is also better than that of internal combustion forklifts.

-

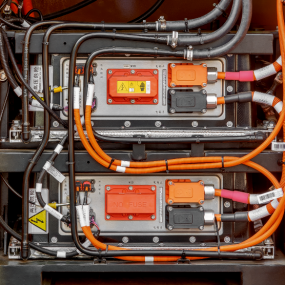

A water cooling system is used for controlling the motor, electric control, and battery. This effectively cools the forklift’s systems so that it can carry out the same long hours and high-intensity operations that internal combustion forklifts are typically found in.

-

The forklift’s high-voltage platform (Standard: 540.96V or Optional: 608.58V) allows for the forklift to run longer in high-intensity operational environments that similar I.C. powered forklifts are found in.

-

The forklift uses a controller that all the systems communicate and then redirects that information to the traction-integrated controller (PDU+DC/DC+MCU). This forms our intelligent driving system and increases the efficiency of the forklift.

- The electrical system is equipped with high voltage interlock and insulation detection to increase the forklift’s safety.

- The MSD maintenance switch enables one-click power-down to increase maintenance safety.

- Using some of the same key structural parts found in our I.C. Pneumatic Forklifts ensures the components’ safety and reliability as they have been used in the market for many years.

- The forklift uses an electric tilting cylinder to tilt the full cabin. By using an electric cylinder, operators are able to save time and effort when tilting the cabin.

- After tilting the full cabin, mechanics are able to easily maintain and/or repair the forklift thanks to the wide opening.

- The cover of the vehicle is designed to be sealed to the water resistance level of IPX4. All the motor, electronic controls and high-voltage components are also rated to the dust and water resistance level of IP67. This high protection level allows the forklift to withstand harsh operating environments and ensures safety and reliability.

- Lithium-ion technology (Lithium Iron-Phosphate), was developed jointly by HANGCHA and CATL for use in material handling equipment applications. These innovative and reliable battery cells and modules are manufactured to the highest standard by CATL exclusively for HANGCHA’s forklift line.

- Rapid and opportunity charging ensures continuous availability of the material handling equipment.

- Lightweight design, highly efficient, maintenance-free, and long service life are all benefits of the XH Series.

- The newly designed chassis has a low center of gravity allowing the operator to feel stable while turning the forklift thanks to being designed around the lithium-ion technology.

- The Integrated Battery Management System (BMS) continually monitors energy management and ensures reliable operation. HANGCHA provides the Lithium Iron Phosphate battery packs with up to a 10 year or 20,000 hour warranty.

- Limited Free Lift 2 Stage Mast

- Hydraulic Prong Adjustment

- Standard Forks

- Fully Hydraulic Power Steering

- Quadruple Multiway Valve

- Air Pneumatic Tires

- Manual/Electric Tipping Pump

- Oil Resistant Tire Tread

- Dual Charging Ports

- Full Cabin

- Horn

- Tow Pin

- Rearview Mirror

- Suspension Seat

- Multi-Directional Joystick

- Air Conditioner & Heater

- Operator Presence Sensing System (OPS)

- Adjustable Steering Wheel

- Multi-Directional Adjustable Armrest

- Multi-Function LCD Instrument Display

- Neutral Switch & Indicator

- Single Drive Motor

- VCU Controller

- Tilting Hydraulic System

- Self-Locking Valve Limit Valve

- Reverse Camera

- Reverse Alarm

- Low Pressure Alarm for the Accumulator

- Hydraulic Oil Filter Alarm

- Emergency Cut-Off Switch

- MSD Maintenance Switch

- Automatic Fire Suppression System for Battery Pack

- Highly Efficient LED Lights

- Strobe Light

- 541V/228Ah or 608V/302Ah Lithium Iron Phosphate (LiFePO4) Battery Pack (Depending on model)

- Water Cooling System for Battery Pack, Control System, and Motor

- 4-in-1 MCU

- Customizable Color

- Various Fork Carriage Sizes

- Various Mast Specifications

- Solid Pneumatic Tires

- Vehicle Intercom System

- Reverse Alarm

- Strobe Light (with/without a control switch)

- Front and/or Rearview Camera (with optional memory)

- Fire Extinguisher (4.4lb/8.7lb)

- Operator Fan

- Mast Installed LED Working Light

- Remote Monitoring System

- Speed Limiter

- Left/Right Blue Lights and Rear Single Line Red Light

- Scale System